-

GaoxinQu, Xingtan, Shunde, Guangdong

Smart Truck Covers: Anti-Theft Tech & 9.5% Market Growth

A seemingly simple metal or fabric cover is quietly becoming a key line of defense for global logistics safety and efficiency.

Truck rear covers have long surpassed the role of a simple “cover” and have become a core equipment for ensuring cargo safety, improving transportation efficiency and reducing operating costs. With the booming global logistics industry, the truck rear cover market has shown a strong growth trend. According to QYR statistics, the global truck rear cover market sales will reach US$1.369 billion in 2024, and is expected to climb to US$2.566 billion by 2031, with an annual compound growth rate of 9.5%.

North America leads the global market with an absolute share of 62%, followed by Europe with 18%. Leading companies such as Truck Hero, Mountain Top Industries and Sunwood Industries together account for 70% of the market share.

1.Upgraded security protection functions, from basic shielding to active defense

Cargo safety has always been the core pain point of the transportation industry. Traditional open cargo compartments face two major threats: weather erosion and theft risk. High-quality rear covers form a physical barrier through a precise sealing structure, effectively blocking rain and snow penetration, ensuring that precision instruments, agricultural products or industrial parts are protected from humidity during long-distance transportation.

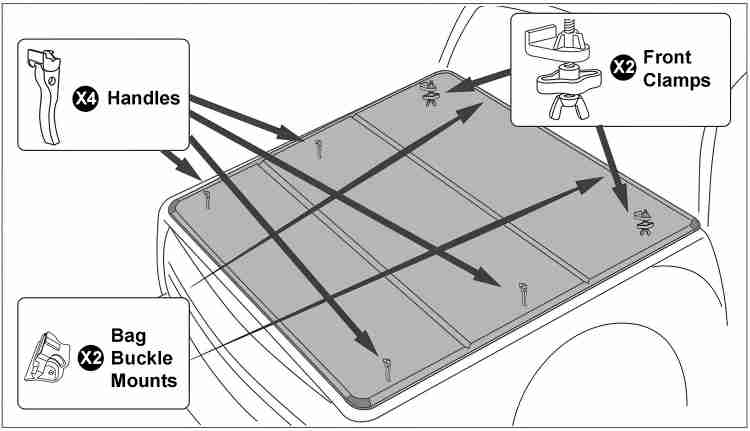

Anti-theft performance is the focus of modern rear cover design. Hard rear covers (such as three-door high covers) with reinforced lock systems can resist external damage. User feedback shows that manganese steel rear covers are rapidly gaining market favor due to their strong load-bearing capacity, no need for drilling and installation, and no damage to the body.

Safety needs are listed as the first priority in consumer surveys, accounting for more than 75%.

2.Diversified materials and structural innovations to match the needs of multiple scenarios

The rear cover market has formed a rich product matrix, which is mainly divided into three types: hard folding, soft folding and retractable. Material selection directly affects product performance and life:

- Cold-rolled steel plate: Great Wall Fengjun high-top rear cover adopts 1.2mm double-layer cold steel plate, which is molded by stamping and supplemented by electrophoresis anti-rust, providing industrial-grade impact resistance.

- Aluminum alloy: The aluminum alloy rear cover launched by Jiangsu Tongfa and other companies has both lightweight and high-strength characteristics, and the powder spraying process ensures weather resistance, which is particularly suitable for high-frequency logistics scenarios.

- Composite fabric: The Oxford cloth soft cover of Dongfeng Ruiqi pickup truck is waterproof and fold-resistant through composite coating, and the combination of carbon steel frame and stainless steel bracket balances cost and performance.

Retractable rear cover has grown significantly in recent years. It uses polycarbonate or glass fiber material retractable sheet layer to achieve “on-demand coverage”, which is particularly suitable for scenes such as construction sites where goods need to be frequently stored and retrieved.

3.Aerodynamics and fuel efficiency, underestimated economic contribution

The role of rear cover in reducing vehicle wind resistance has long been underestimated. Actual measured data shows that installing a streamlined rear cover can reduce tail turbulence and reduce the drag coefficient by 15%-20%. For a freight fleet that travels 80,000 kilometers per year, this means that fuel consumption can be reduced by 5%-8%, which directly translates into considerable operating cost savings.

North American and European users pay the most attention to this feature, and fuel efficiency demand has become the second largest decision-making factor in purchasing rear covers.

4.The wave of intelligence and electrification redefines the boundaries of functions

Internet of Things technology is driving the evolution of rear covers towards intelligence. High-end models have integrated electric opening, APP control and safety sensors. For example, some European and American manufacturers have launched rear cover systems that support remote locking/alarm linkage, and abnormal movement of goods can be pushed to the owner’s mobile phone in real time.

The application of smart materials is also worthy of attention. Self-cleaning coatings can reduce maintenance frequency, and embedded solar panels provide auxiliary power for on-board electronic equipment. These innovations have transformed the rear cover from passive protection to active function integration.

5.Global market structure and regional characteristics, North America dominates and Asia-Pacific rises

The market shows significant regional differentiation. North America relies on pickup culture popularization and large logistics enterprises concentration, accounting for 62% of the global market share. The European market drives the demand for high-end hard covers with strict cargo safety standards.

Although the Asia-Pacific market is small in scale, it has huge growth potential. Chinese manufacturers such as Jiangsu Tongfa and Henan Senyi have rapidly penetrated through localized adaptation: for example, the high-top rear cover developed by Senyi for Great Wall Fengjun 5/6/7 accurately matches the cargo compartment size of local best-selling models. The compound annual growth rate of the Chinese market is expected to exceed the global average, and the share is expected to increase significantly in 2031.

6.Customized and scenario-based solutions, the rise of industry-specific designs

Standardized products are difficult to meet the needs of subdivided industries, and customized solutions have become a new high ground for competition. Cold chain logistics requires a rear cover with reinforced insulation layer, while the transportation of hazardous chemicals requires anti-static and explosion-proof design. The e-commerce express delivery industry promotes the development of “segmented opening” rear covers, which facilitates the efficient loading and unloading of scattered goods.

Aftermarket is still the mainstream channel, but the OEM pre-installation rate continues to rise. Toyota, Ford and other automakers have included high-end rear covers in the optional packages of new cars to achieve seamless integration with the original car’s electronic control system.

Customization demand has grown fastest in the construction industry and agricultural transportation, with an annual growth rate of more than 12%.

Retractable rear covers have a penetration rate of 34% in the e-commerce logistics field due to their flexible adaptation to different cargo heights; manganese steel three-door high covers protect the integrity of the vehicle body with “zero drilling installation” technology, becoming the first choice for individual car owners; carbon fiber materials, although expensive, have a place in the high-end market with a 40% lightweight advantage.

The global rear cover market is evolving towards intelligence and greening. As more companies join the ISO/e-mark certification system, product quality and international compatibility will continue to improve. When a piece of steel plate is combined with a smart chip, the evolution of truck hoods has just turned over the prologue.

Truck hoods, once regarded as “tin boxes”, are quietly transforming into smart guardians of logistics safety.