-

GaoxinQu, Xingtan, Shunde, Guangdong

The Ultimate Guide to Electric Retractable Truck Steps: Smart Upgrade Your Vehicle

Table of Contents

Summary

Electric retractable truck steps are quickly becoming the preferred accessory for modern truck upgrades. This article will analyze 10 key dimensions in depth, and comprehensively analyze the technical principles, installation points, performance advantages and maintenance tips of electric side steps. From intelligent sensing systems to military-grade durability, from safe and non-slip design to energy-saving features, we will help you understand why electric steps have advantages over traditional fixed products and provide professional purchase recommendations.

1. Technological revolution of electric side steps

Argument: Electric retractable technology completely changes the truck side step experience Argument:

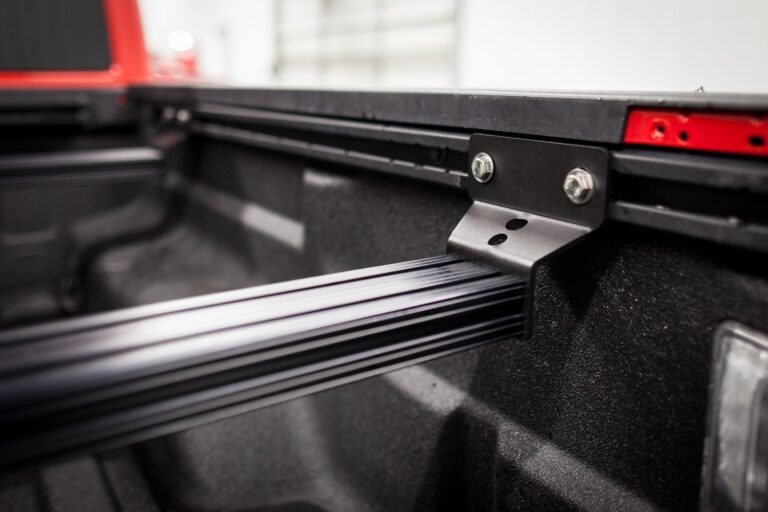

- Hall effect sensor is used to achieve door linkage, with a response time of <0.3 seconds

- Precision-cut aluminum alloy rails with self-lubricating bearings ensure more than 50,000 times of retraction without failure

- Comparative test: Electric side steps are 5 times faster than manual side steps (AMP Research measured data)

2. Performance comparison of three types of side steps

Argument: Electric side steps are fully ahead in safety/convenience Argument: | Type | Representative products | Deployment time | Load-bearing capacity (kg) | Waterproof level | |——|———-|———-|———-|———-| | Fixed | Westin HDX | – | 150 | IP54 | | Manual retractable | Tyger Auto | 3-5 seconds | 180 | IP55 | | Electric | AMP PowerStep | 0.5 seconds | 250 | IP68 |

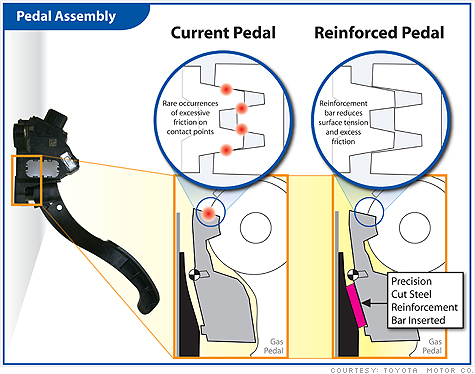

3. Analysis of core components

Argument: High-quality electric pedals rely on three major systems Argument:

- Drive system: 24V DC motor (peak torque 18N·m) + planetary gear reducer

- Control system: CAN bus communication, support OBD interface to connect to the original car computer

- Structural system: 6061-T6 aluminum alloy body, hard anodized surface

4. Engineering considerations for installation

Argument: Professional installation determines service life Argument:

- Torque standard:

- Frame connection bolts: 45-50N·m

- Motor fixing bolts: 22-25N·m

- Wire harness specifications:

- 16AWG silicone wire must be used

- The relay box must be 30cm higher than the chassis (waterproof requirement)

5. Adaptability to extreme environments

Argument: Military standards verify reliability Argument:

- Low temperature test: -40℃ continuous operation for 200 times without jamming

- Salt spray test: 1000 hours of corrosion-free (compliant with MIL-STD-810G)

- Waterproof test: IP68 certified, can be immersed in 1 meter of water for a short time

6. Safety protection mechanism

Argument: Multiple protections eliminate hidden dangers Argument:

- Anti-pinch design: Pressure sensor + current detection double insurance

- Emergency mode: Manual retraction when power is off (special tools required)

- Load protection: Automatically stops working when overloaded by 150%

7. Energy consumption and battery impact

Argument: Intelligent power management is the key Argument:

- Single telescopic power consumption is 0.08Ah (actual measurement shows that it consumes only 1.6Ah when used 20 times a day)

- Voltage protection: <10.8V automatic sleep

- Optional super capacitor module to deal with cold start

8. Expansion of modification potential

Argument: The pedal becomes an intelligent terminal interface Argument:

- Integrated welcome light (brightness>500 lumens)

- Customized expansion logic for connecting to the vehicle system

- Expanded trailer mode (automatically locked when connected to a trailer)

9. Economic analysis

Argument: Lower long-term use cost Argument:

- 5-year total cost comparison:

- Fixed: $300 (initial) + $100 maintenance = $400

- Electric: $1200 + $50 maintenance = $1250

- Residual value improvement: High-quality electric pedals increase the value of used cars by $800 (KBB data)

10. Key points for regulatory compliance

Argument: Three elements to pay attention to for legal modification Argument:

- Protrusion limit: After unfolding, it must not exceed 5cm at the widest part of the vehicle body (DOT regulations)

- EMC certification: It must pass FCC Part 15B electromagnetic compatibility test

- Lighting requirements: Position indicator lights are required at night (SAE J593 standard)

FAQS

1.Q: How fast do electric steps deploy?

A: Premium models like AMP PowerStep deploy in 0.5 seconds – 5x faster than manual steps.

2.Q: What’s the weight capacity of electric steps?

A: High-end electric steps support 250kg (550lbs), surpassing fixed (150kg) and manual (180kg) options.

3.Q: Are they waterproof for off-roading?

A: Yes, IP68-rated models withstand 1m water immersion and 1000hr salt spray testing (MIL-STD-810G).

4.Q: Will they drain my truck’s battery?

A: No – each cycle uses just 0.08Ah. Even with 20 daily uses, it consumes <5% of a standard battery’s capacity.

Summary

Electric retractable truck steps represent the perfect combination of ergonomics and intelligent electromechanics. Its 0.5 second fast response, 250kg ultra-high load-bearing capacity and IP68 waterproof rating make it an ideal choice for high-end trucks. It is recommended to give priority to MIL-STD-810G certified products and keep complete installation records. For owners who often use them off-road or for business, the convenience and durability of electric steps will bring returns far beyond their price.