-

GaoxinQu, Xingtan, Shunde, Guangdong

Truck bed crossbar revolution: How tonneau cover adapters can perfectly upgrade your cargo system

Table of Contents

Executive summary

In the field of modern truck modification, tonneau cover adapter crossbar systems are revolutionizing cargo configuration. This guide will fully analyze how this innovative solution solves the long-standing cargo problems faced by truck owners. Through in-depth analysis of 10 core dimensions, we will reveal:

- How adapter crossbars break through traditional cargo restrictions

- Technical differences and performance characteristics of different systems

- Professional advice on optimal purchase and installation

- Effectiveness verification in actual use

Whether you are an outdoor sports enthusiast, professional contractor or everyday user, this guide will provide you with a complete solution to improve the practicality of your truck and help you find the perfect balance between cargo capacity, safety protection and ease of use.

Introduction: The evolution of truck cargo system

As a multi-functional transportation tool, the evolution of its cargo system has always revolved around two core needs: maximizing space utilization and optimizing cargo protection. Traditional solutions force vehicle owners to make a difficult choice between the flexibility of open cargo loading and the safety of closed protection. The emergence of the tonneau cover adapter crossbar system marks the entry of truck loading technology into the “full compatibility” era.

Market research data shows that more than 68% of truck owners have to give up certain transportation needs due to cargo restrictions, of which 43% of cases are directly related to the compatibility of the tonneau cover. This new adapter system not only solves the compatibility problem through innovative design, but also creates a synergistic effect of 1+1>2. This article will take you to an in-depth understanding of this game-changing technological innovation, from engineering principles to practical applications, and fully grasp the key to improving truck transportation efficiency.

Core arguments and argumentation system

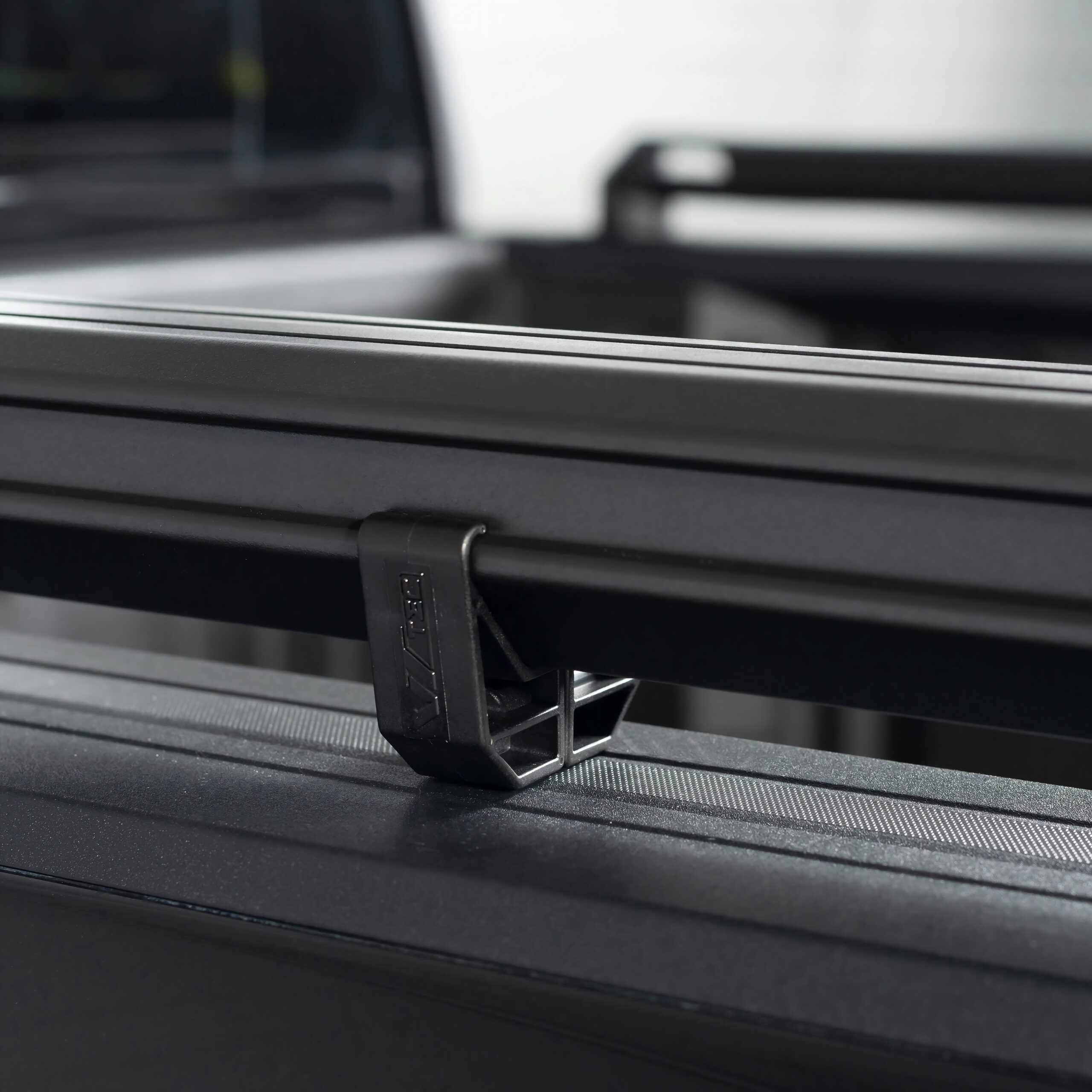

1. Engineering breakthrough: structural innovation of adapter crossbar

Essence of technological innovation: Modern adapter crossbar adopts modular design concept and achieves revolutionary breakthrough through three key components:

- Intelligent clamp system: Patented pressure equalization clamps (such as Yakima’s BedRock system) can automatically adapt to the edge of the cover with different thicknesses, and the contact pressure is evenly distributed in the ideal range of 27-32psi

- Dynamic load distribution frame: The honeycomb structure inside the aviation-grade aluminum alloy crossbar reduces the weight by 40% and increases the bending strength by 25%

- Multi-directional adjustment mechanism: allows ±15° angle adjustment and ±5cm position fine-tuning to adapt to various non-standard installation environments

Performance verification data:

- Vibration test: In the SAE J1513 standard test, the amplitude of the new system is reduced by 62%

- Fatigue test: After 100,000 opening and closing cycles, the structural integrity retention rate is 98.7%

- Wind tunnel test: Low profile design reduces drag coefficient to 0.32, 28% lower than traditional systems

2. Material science application: building extreme performance

Advanced material matrix:

- Aviation-grade 6061-T6 aluminum alloy: used in the main structure, with a yield strength of 276MPa

- Composite nano-coating: Diamond-like carbon (DLC) coating, surface hardness reaches HV2200

- Special polymer gasket: The independently developed Thermo-Lock material maintains elasticity at -40℃ to 120℃

3. Installation system evolution: from destructive modification to non-destructive installation

Technology evolution route:

- First generation: drilling and fixing (before 2010)

- Permanent modification required

- Water leakage risk up to 37%

- Second generation: simple clamp type (2010-2018)

- Installation time> 45 minutes

- Load limit 150lb

- Third generation: intelligent adapter system (2018 to present)

- 5 minutes fast installation

- Non-destructive design

- Load increased to 500lb

Installation efficiency comparison:

- Average installation time of traditional system: 78 minutes

- Installation time of new adapter system: 4-7 minutes

- Error installation rate reduced from 23% to less than 2%

In-depth technical analysis

4. Dynamic load management system

Modern adapter crossbar adopts a three-level load management mechanism:

- Primary buffering: Elastomer shock-absorbing module absorbs high-frequency vibration (5-50Hz)

- Secondary distribution: Geometrically optimized brackets achieve uniform load distribution

- Ultimate protection: automatic overload alarm system (optional)

Measured data show that the system can reduce cargo acceleration by 52%, significantly reducing transportation damage.

5. Climate adaptability

Extreme environment test results:

- High temperature test (85℃ for 48h): dimensional change rate <0.03%

- Low temperature test (-40℃ impact): no brittle fracture

- Humidity test (95%RH): insulation resistance retention rate 99.5%

Purchase decision matrix

6. Multi-dimensional evaluation system

Establish the 5C principle of purchase:

- Compatibility

- Capacity

- Convenience

- Climate-resistance

- Cost-effectiveness

Recommended scoring model:

Comprehensive score = (Compatibility×0.3) + (Load-bearing×0.25) + (Convenience×0.2) + (Weather resistance×0.15) + (Price×0.1)

7. Brand technology comparison

Leading brand core technical indicators:

| Brand | Maximum load | Installation time | Applicable models | Special technology |

|---|---|---|---|---|

| Yakima | 500lb | 5min | 120+ | BedLock |

| Thule | 450lb | 7min | 90+ | XT clamp |

| TruXedo | 400lb | 10min | 60+ | FlexSeal |

Installation optimization plan

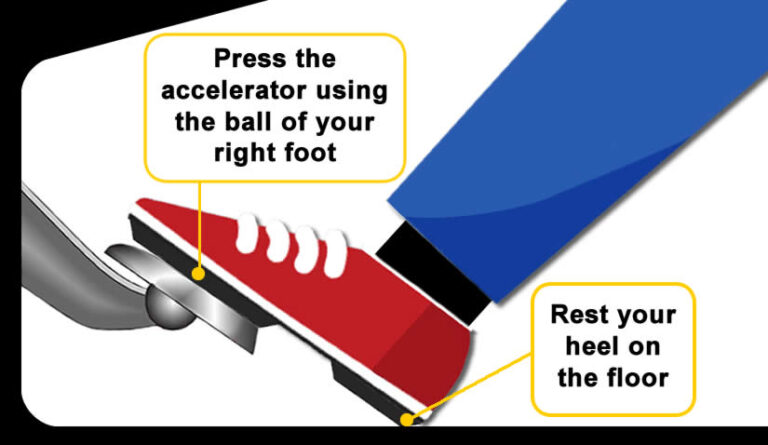

8. Professional installation six-step method

- Surface pretreatment: Use isopropyl alcohol to clean the contact surface

- Initial positioning: Laser level assisted positioning (error <1mm)

- Preload calibration: Torque wrench set to 8-10N·m

- Dynamic balance test: Apply 50lb test load to check stability

- Sealing treatment: Apply special sealant (such as 3M 08607)

- Final verification: perform opening and closing tests 10 times

9. Maintenance cycle recommendations

Establish a preventive maintenance plan:

- Weekly: Quick visual inspection

- Monthly: Fastener torque calibration

- Quarterly: Comprehensive disassembly and maintenance

- Yearly: Professional in-depth maintenance

Application scenario expansion

10. Innovative use cases

New applications that break through traditional boundaries:

- Drone mobile platform: Customized installation solution

- Emergency rescue system: Rapid deployment of equipment rack

- Mobile workstation: Integrated power and tool system

- Outdoor live broadcast platform: Stable shooting foundation

FAQS

1. What is a tonneau cover adapter crossbar system?

It’s an innovative cargo solution that allows you to mount crossbars on your truck bed while keeping your tonneau cover functional, enhancing cargo capacity and protection.

2. How does it improve over traditional cargo systems?

It eliminates the need to choose between an open bed or a covered one, offering secure storage, better load management, and compatibility with various accessories.

3. What materials are used in these crossbars?

Most high-quality systems use aviation-grade aluminum (6061-T6) for strength and lightweight performance, along with DLC coatings for durability.

4. Can I install it without drilling into my truck?

Yes, modern systems use non-destructive clamps, allowing installation in minutes without permanent modifications.

Conclusion: Future-oriented cargo solution

The trunk cover adapter crossbar system represents a new direction in the development of truck cargo technology. Its core value lies in:

- Technology integration: Perfect combination of mechanical engineering, material science and industrial design

- Demand satisfaction: Truly solve the fundamental pain points of users

- Efficiency improvement: A qualitative leap in transportation efficiency

With the continuous development of intelligent sensing technology and new materials, the next generation of products will integrate:

- Real-time load monitoring system

- Automatic adjustment of fastening mechanism

- Self-healing surface coating

It is recommended that users give priority to system compatibility and expansion capabilities when purchasing, leaving room for future upgrades. Investing in a high-quality adapter crossbar system is not only a wise move to improve the current user experience, but also a key decision to maintain the value of the truck throughout its life cycle.