-

GaoxinQu, Xingtan, Shunde, Guangdong

The Ultimate Step-by-Step Guide to Installing a Tonneau Cover

Table of Contents

Summary

As an essential truck accessory, a tonneau cover not only protects your cargo, but also improves your vehicle’s aerodynamics. This article will provide you with a comprehensive guide from tonneau cover types, key points to consider, to detailed installation steps. Whether you are a first-time installer or an experienced driver looking to upgrade your existing tonneau cover, this guide will help you choose the best product and complete a professional-level installation. We will highlight the pros and cons of soft, hard, and hybrid tonneau covers, provide a detailed tool list and installation tips, and share long-term maintenance recommendations to ensure your tonneau cover lasts.

Chapter 1: Comprehensive understanding of truck bed cover types and features

1.1 Basic concepts and functions of truck bed covers

Truck bed covers are protective devices installed on the top of truck cargo boxes. Their main functions include:

- Cargo protection: prevent damage to cargo from environmental factors such as rain, dust, and ultraviolet rays

- Security: reduce the risk of cargo theft, especially valuable tools and equipment

- Aerodynamic optimization: reduce driving wind resistance and improve fuel economy

- Appearance improvement: make the overall shape of the truck more beautiful and smooth

Modern truck bed covers have developed a variety of materials and structural designs, from the most basic soft canvas cover to high-tech electric hard cover, to meet the needs of different users.

1.2 In-depth analysis of mainstream truck bed cover types

1.2.1 Soft truck bed cover

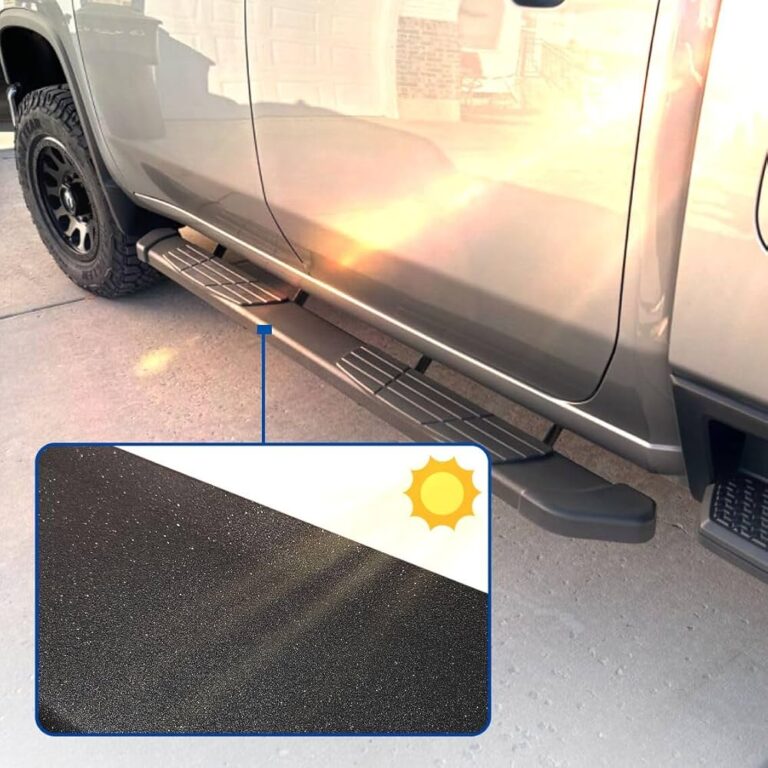

Material characteristics: It uses high-density vinyl (Vinyl) or polyester fiber (Polyester) fabrics, and the surface is usually treated with PVC coating, which has waterproof and UV protection functions. High-quality products will add a glass fiber reinforcement layer to improve tear resistance.

Main styles:

- Roller type: Smooth opening and closing through the guide rail system on both sides, equipped with spring or electric motor assistance

- Buckle type: Traditional design, relying on metal buckles to fix the surroundings, simple installation but general sealing

- Pull rope type: Quickly unfold or fold through the central pull rope, easy to operate

Performance characteristics:

- The weight is usually 10-15kg, which has little impact on the vehicle load

- The height of the cargo box remains basically unchanged after installation, and does not affect the passability

- The wind resistance is weak, and shaking problems may occur when driving at high speeds

- The service life is about 3-5 years, and the aging of the fabric needs to be checked regularly

Representative brands: TruXedo, Access, Tyger Auto and other brands provide a variety of price options, from economy to high-end models.

1.2.2 Hard Truck Back Cover

Material Selection:

- Aluminum Alloy: Lightweight (20-30kg), rust-proof, moderate cost

- Fiberglass: Strong modeling ability, can be made into streamlined shape, but heavier (30-40kg)

- Polycarbonate: Strong impact resistance, high transparency, suitable for scenes requiring lighting

Structural Type:

- Folding: Divided into three-fold or four-fold design, can be partially or fully opened

- Telescopic: Slide forward and backward through the guide rail system to save space

- Hatchback: Open as a whole, providing maximum loading and unloading space

- Electric: Equipped with motor and remote control system, the most convenient operation

Advantage Analysis:

- Excellent anti-theft performance, most products are equipped with reinforced locks

- Excellent aerodynamic performance, can reduce high-speed fuel consumption by 5-10%

- Long service life of 8-10 years, low maintenance cost

- Can be integrated with cargo box lighting, reversing camera and other equipment

Representative products: Brands such as BakFlip, Retrax, UnderCover, etc. provide hard back covers at various prices, and some high-end models also support intelligent control.

1.2.3 Hybrid Truck Hood

Design Features: Combines the flexibility of soft materials and the stability of hard frames, for example:

- Aluminum alloy frame + high-strength canvas

- Folding hard board + flexible connector

- Electric roller shutter + metal end cap

Applicable scenarios:

- Users who need to balance durability and lightness

- Users with limited budgets but want to get performance close to that of hard hoods

- When standard hoods with special cargo box shapes cannot meet the requirements

1.3 In-depth analysis of key factors in purchasing

1. Cargo box matching

- Measure the length, width, and depth of the cargo box (front/middle/rear three points)

- Pay attention to whether there is a special shape on the top of the cargo box (such as a corrugated board)

- Check the position and shape of the tailgate sealing strip

2. Use environment considerations

- Rainy areas: Choose a fully sealed design and pay attention to the drainage system

- High temperature areas: Prefer light-colored surfaces and consider insulation

- Cold regions: Choose low-temperature resistant materials (below -30℃)

3. Functional requirements

- Frequent loading and unloading: Folding or rolling shutter is more convenient

- Valuables transportation: Hard rear cover + multi-point locks

- Special equipment: Consider load-bearing capacity (such as roof rack)

4. Budget planning

- Soft: $200-$800

- Hard: $800-$3000

- Electric: $1500-$5000

Chapter 2: Professional installation tools and preparations

2.1 List of necessary tools

Basic tools:

- Torque wrench (10-50Nm range)

- Cross/slotted screwdriver set

- Socket wrench set (8mm-15mm)

- Rubber hammer (for adjusting position)

- Electrical tape (temporary fixing of wiring harness)

Special tools:

- Guide rail positioning fixture (for some brands only)

- Wiring harness waterproof connector (required for electric models)

- 3M double-sided tape (auxiliary fixing seal strip)

- Silicone lubricant (guide rail maintenance)

Safety equipment:

- Cut-resistant gloves

- Goggles

- Stable climbing ladder

2.2 Pre-installation inspection items

Vehicle preparation:

- Thoroughly clean the top of the cargo box to remove dust and oil

- Check whether the two sides of the cargo box are symmetrical and deformed

- Confirm that all on-board tools have been removed

- Disconnect the negative terminal of the battery (required for electric models)

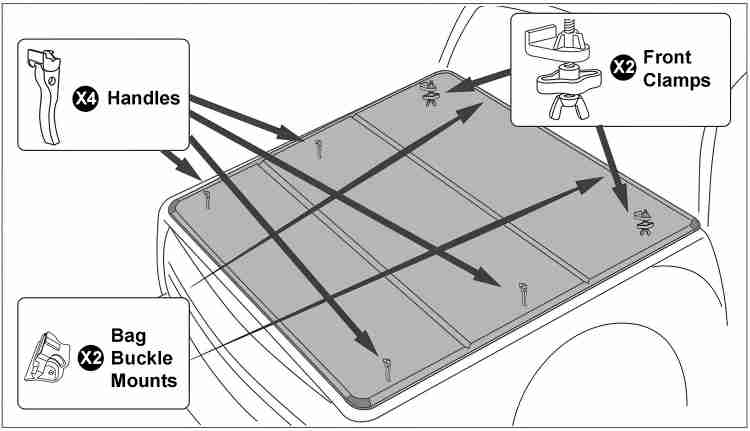

Accessory verification:

- Check all parts against the checklist

- Test whether the electric parts are working properly

- Pre-assemble complex parts (such as folding mechanisms)

Environment selection:

- Flat hard ground

- Adequate light conditions

- Windless or breezy weather (to avoid parts blowing off)

Chapter 3: Detailed installation steps analysis

3.1 Soft rear cover installation process

Step 1: Side rail installation

- Use alcohol to clean the installation contact surface

- Temporarily fix first and confirm the front and rear positions are correct

- Tighten at the recommended torque (usually 8-10Nm)

Step 2: Front fixation

- Ensure that the gap between the front seal and the cab is uniform

- Use a level to check the front and rear levelness

Step 3: Tension adjustment

- Adjust both sides simultaneously to avoid deflection

- Test the smoothness of opening and closing, without sticking

Professional tips: Avoid high-speed driving within 48 hours after installation to allow the material to fully stretch and shape

3.2 Key points for hard rear cover installation

Step 1: Bracket positioning

- Use a laser level to ensure left and right symmetry

- Double check before marking the drilling position

Step 2: Electrical connection

- Avoid high-temperature areas when routing the wiring harness

- All joints are waterproofed

- Fix the panel after testing the electric function

Step 3: Sealing test

- Use a water pipe to simulate rainfall test

- Focus on checking the sealing of the four corners

- Adjust the lock position to improve the sealing if necessary

Safety warning: Two or more people should work together, especially when lifting a large hard rear cover

Chapter 4: Maintenance and troubleshooting

4.1 Daily maintenance specifications

Cleaning suggestions:

- Soft: Special detergent + soft brush

- Hard: Car wax to maintain the surface coating

- Guide rail: Silicone grease lubrication once a month

Seasonal maintenance:

- Check the elasticity of the sealing strip before winter

- Clean the drainage channel before the rainy season

- It is recommended to park in a half-open state for long-term parking

4.2 Solutions to common problems

Problem 1: Water leakage treatment

- Check whether the sealing strip is aging

- Adjust the lock pressure distribution

- Replenish sealant (specific location)

Problem 2: Abnormal sound diagnosis

- Remove foreign matter from the guide rail

- Lubricate the hinge part

- Fastener torque review

Problem 3: Electric failure

- Check the fuse

- Test switch signal

- Reset control module

Chapter 5: Product recommendations and purchase suggestions

5.1 Recommended products for each price range

Economy ($200-$500):

- TruXedo TruXport soft roller blinds

- Tyger Auto T1 soft clip-on type

Mid-range ($500-$1500):

- BakFlip MX4 hard folding type

- RetraxONE XR telescopic type

High-end ($1500+):

- Roll-N-Lock M series electric type

- Pace Edwards Ultragroove fully automatic

5.2 Comparison of purchase channels

Online advantages:

- Transparent prices

- Complete styles

- User evaluation reference

Offline advantages:

- Physical experience

- Professional installation service

- Fast after-sales response

Recommendations: For bulk purchases, give priority to brand-owned stores to enjoy full warranty

FAQS

1. What tools do I need to install a tonneau cover?

Basic tools include a torque wrench (10-50Nm), screwdrivers, socket set, and rubber hammer. Electric models require additional wiring tools.

2. How long does installation take?

Soft covers: 15-30 minutes

Hard folding covers: 1-2 hours

Retractable/electric covers: 2-3 hours (may need professional help)

3. Can I install a tonneau cover by myself?

Yes for most soft/folding covers. Hard retractable covers often require 2+ people due to weight.

4. Do I need to drill into my truck bed?

Most modern covers use clamp-on systems – no drilling required unless specified for certain heavy-duty models.

Summary

The selection and installation of a truck cover is a decision-making process that requires comprehensive consideration of multiple factors. With the detailed guide in this article, you should have mastered all the key points from product selection to professional installation. Remember, the right cover not only improves the truck experience, but also protects the safety of your cargo and optimizes fuel economy. It is recommended to perform regular maintenance and contact professional service personnel in time when encountering complex problems. Start choosing the most suitable truck cover for your car now!